S&S Motorcycle Engines: Expert Breakdown of Performance Engineering Excellence

S&S Cycle stands as one of the most respected names in the motorcycle aftermarket industry, particularly renowned for their high-performance engine components and complete powerplant solutions. Founded in 1958 by George Smith in Laconia, New Hampshire, the company has evolved from a small operation into a global leader in custom motorcycle engineering. Their expertise in engine design, manufacturing precision, and performance optimization has made S&S engines the preferred choice for builders, enthusiasts, and manufacturers seeking to maximize motorcycle performance without compromising reliability or durability.

The motorcycle engine market demands exceptional engineering standards, rigorous quality control, and continuous innovation to remain competitive. S&S Cycle has maintained its market leadership through decades of research and development, strategic partnerships with major manufacturers, and an unwavering commitment to performance excellence. Understanding the S&S motorcycle company requires examining their product portfolio, manufacturing capabilities, market positioning, and the strategic factors that have sustained their competitive advantage in a dynamic industry landscape.

Company Overview and Market Position

S&S Cycle operates within the specialized segment of the motorcycle aftermarket, where premium pricing reflects engineering superiority and performance gains. The company’s market position has been built on several foundational pillars: exceptional engineering talent, proprietary manufacturing processes, and decades of accumulated technical expertise. With headquarters in Madison, Wisconsin, S&S maintains manufacturing facilities that combine advanced CNC machining with skilled craftspeople who understand the nuances of high-performance engine building.

The motorcycle engine market encompasses several distinct segments: original equipment manufacturers (OEMs) seeking engine solutions for production models, custom builders requiring high-displacement powerplants, and performance enthusiasts pursuing incremental horsepower gains. S&S Cycle serves all three segments effectively, which diversifies revenue streams and reduces dependency on any single market sector. This strategic approach aligns with fundamental business sustainability strategies that emphasize portfolio diversification and market resilience.

The company’s competitive positioning reflects several distinctive advantages. First, S&S maintains strict quality control standards that exceed industry norms, ensuring that engines delivered to customers perform consistently across diverse riding conditions and applications. Second, their engineering team continuously develops proprietary technologies that competitors struggle to replicate, creating sustainable differentiation. Third, S&S has cultivated strong relationships with major motorcycle manufacturers, including Harley-Davidson, Indian, and numerous international brands, providing stable revenue foundations alongside aftermarket sales.

Engine Technology and Performance Innovation

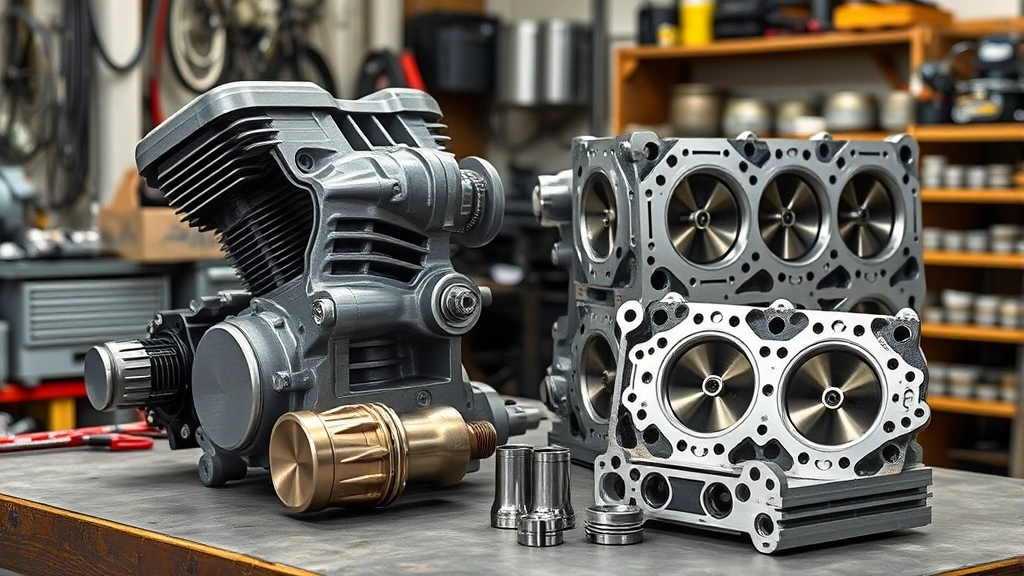

S&S Cycle’s technological capabilities represent the core of their competitive advantage. The company specializes in air-cooled V-twin engine design and manufacturing, a market segment where precision engineering directly translates to performance and reliability. Their engine platforms range from modest displacement increases suitable for stock-frame applications to massive displacement powerplants exceeding 125 cubic inches, delivering horsepower figures that transform motorcycle performance characteristics.

The engineering approach employed by S&S demonstrates sophisticated understanding of thermodynamic principles, mechanical stress distribution, and materials science. Their engine development process incorporates extensive dyno testing, computer-aided design simulation, and real-world validation through partnership with professional riders and builders. This rigorous methodology ensures that performance claims translate to measurable, repeatable results rather than theoretical specifications.

Key technological innovations within S&S engine platforms include:

- Advanced cylinder head design incorporating optimized port shapes and combustion chamber geometry that enhances fuel mixture velocity and combustion efficiency

- Precision-forged internal components utilizing high-strength materials capable of withstanding extreme pressure and temperature conditions

- Variable valve timing systems that adjust intake and exhaust valve overlap based on engine operating conditions, improving low-end torque and high-RPM power production

- Proprietary fuel injection calibration developed specifically for S&S engine characteristics, ensuring optimal air-fuel ratios across the entire power band

- Enhanced cooling jacket designs that maintain optimal operating temperatures even in high-performance applications

The company’s commitment to continuous improvement drives regular updates to existing platforms and development of entirely new engine families. This innovation strategy requires substantial investment in research and development, testing facilities, and technical talent retention. S&S allocates significant resources to these functions because performance leadership demands constant evolution as competitors introduce new technologies and customer expectations escalate.

Product Portfolio and Applications

S&S Cycle’s product portfolio encompasses complete engines, long-block assemblies, short-block kits, and individual component offerings. This tiered approach allows customers to select solutions matching their budget constraints, technical capabilities, and performance objectives. Builders seeking complete powerplants can purchase fully assembled, dyno-tested engines ready for installation. Those with existing engine cores can upgrade specific components, such as cylinder head kits or piston assemblies, to achieve incremental performance improvements.

The company manufactures engines specifically engineered for distinct motorcycle platforms. Harley-Davidson applications represent a significant portion of S&S business, with engine solutions designed for Evolution, Twin Cam, and Milwaukee-Eight platforms. Indian motorcycle engines, featuring different architecture and displacement characteristics, require purpose-built S&S solutions. Additionally, S&S develops universal applications suitable for custom builders and independent manufacturers seeking high-quality powerplants for bespoke motorcycle projects.

Displacement options span the market spectrum. Entry-level performers might select 103-cubic-inch engines offering modest power increases with minimal modification requirements. Mid-range enthusiasts gravitate toward 111 to 117 cubic inch platforms providing substantial horsepower gains while maintaining acceptable heat generation and fuel consumption. Extreme performance seekers pursue 124+ cubic inch engines that transform motorcycle acceleration and top-speed characteristics. This portfolio diversity enables S&S to serve customers across price points and performance expectations.

Each engine platform receives dyno certification documenting horsepower and torque output across the operating range. These specifications provide customers with transparent performance expectations and validate engineering claims. Certification testing occurs on professional dynamometers using standardized protocols, ensuring consistency and credibility. This commitment to transparency builds customer confidence and differentiates S&S from competitors making unsubstantiated performance claims.

Manufacturing Excellence and Quality Standards

Manufacturing excellence represents a critical competitive differentiator in the premium motorcycle engine market. S&S Cycle operates state-of-the-art facilities combining advanced computer numerical control (CNC) machining with traditional craftsmanship. This hybrid approach leverages technology for precision and consistency while preserving the human expertise required for quality assurance, assembly optimization, and problem-solving.

The company’s quality management system encompasses rigorous incoming material inspection, in-process monitoring, and final assembly verification. Every engine receives comprehensive testing before shipment, including cold cranking validation, warm-up protocol execution, and performance verification against documented specifications. This systematic approach minimizes defect rates and ensures customers receive products meeting the highest reliability standards.

Material selection reflects S&S’s commitment to durability and performance. The company specifies premium-grade aluminum alloys for cylinder heads and crankcases, high-strength steel forgings for internal components, and specialized coatings that enhance surface durability and thermal management. These material choices increase manufacturing costs compared to competitors utilizing commodity-grade materials, but the resulting performance and longevity justify the premium positioning.

S&S maintains comprehensive documentation standards for every engine produced. Serial number tracking enables complete traceability from manufacturing through final delivery. This capability proves invaluable for warranty administration, technical support, and continuous improvement initiatives. When issues arise, the company can rapidly identify affected production batches and implement corrective actions, demonstrating the kind of business risk management that protects brand reputation and customer satisfaction.

Market Strategy and Competitive Advantages

S&S Cycle’s market strategy reflects sophisticated understanding of customer segments, competitive dynamics, and industry trends. Rather than competing primarily on price, the company emphasizes performance leadership, engineering excellence, and customer support. This positioning enables premium pricing that funds continued innovation and quality investment while attracting customers prioritizing results over cost minimization.

The company’s competitive advantages extend beyond technical superiority. S&S maintains strong brand recognition built through decades of consistent performance delivery and industry visibility. Professional riders, custom builders, and motorcycle manufacturers recognize S&S engines as symbols of performance excellence. This brand equity translates to customer loyalty and enables premium pricing that lesser-known competitors cannot command.

Strategic partnerships strengthen S&S’s market position significantly. Relationships with major OEMs provide stable revenue foundations and market validation of S&S engineering. When Harley-Davidson, Indian, or other manufacturers specify S&S components in production models, it communicates to the broader market that S&S technology meets the highest industry standards. These partnerships also provide valuable feedback about customer preferences, performance requirements, and emerging market trends.

S&S invests substantially in customer support and technical education. The company maintains experienced technical staff available to assist builders with engine selection, installation guidance, and troubleshooting support. This support function enhances customer satisfaction, reduces installation problems, and builds long-term relationships that encourage repeat business and referrals. Many competitors underinvest in support functions, creating opportunities for S&S to differentiate through superior service.

Digital marketing strategies enable S&S to reach enthusiasts and builders effectively. The company maintains an informative website documenting technical specifications, performance data, and installation requirements. Social media presence showcases customer builds, performance achievements, and company developments. This content marketing approach builds community engagement and provides valuable information that supports customer decision-making.

Industry Partnerships and OEM Integration

Original equipment manufacturer partnerships represent strategic assets that strengthen S&S’s competitive position and market reach. These relationships extend beyond simple supplier arrangements; they involve collaborative engineering, joint product development, and integrated supply chain management. When major manufacturers select S&S engines for production models, it validates the company’s engineering capabilities while providing market visibility that benefits the entire product portfolio.

Harley-Davidson represents S&S’s most significant OEM relationship, spanning decades of collaboration. The partnership encompasses engine supply for specific model years, collaborative engineering on performance platforms, and integrated marketing initiatives. This relationship provides S&S with stable revenue streams, early visibility into market trends, and opportunities to influence motorcycle design standards. For Harley-Davidson, partnering with S&S ensures access to high-performance engine solutions that satisfy enthusiast demand without requiring substantial internal development investment.

Indian Motorcycle partnerships similarly provide strategic benefits for both parties. As Indian develops performance-oriented models targeting riders seeking alternatives to traditional Harley-Davidson aesthetics, S&S engines enable manufacturers to deliver distinctive performance characteristics. These partnerships require S&S to develop specialized engine variants suited to Indian platform architecture, demonstrating the company’s engineering flexibility and manufacturing capability.

International partnerships extend S&S’s market reach beyond North American boundaries. European and Asian manufacturers seeking high-performance engine solutions increasingly specify S&S powerplants for custom and performance models. These global relationships diversify revenue sources, reduce exposure to domestic market fluctuations, and position S&S as a truly international competitor rather than a regional specialist.

Sustainability and Future Growth

The motorcycle industry faces significant technological transformation driven by environmental regulations, changing consumer preferences, and electrification trends. S&S Cycle’s future success depends on strategic adaptation to these evolving conditions while maintaining the performance leadership that defines the brand. Understanding how the company addresses these challenges provides insight into long-term viability and growth prospects.

Regulatory pressures increasingly impact traditional internal combustion engine development. Environmental standards, emissions regulations, and fuel efficiency requirements constrain displacement increases and horsepower gains that previously defined performance advancement. S&S responds by developing technologies that maximize performance within regulatory constraints, such as advanced fuel injection systems, optimized combustion chamber designs, and efficiency-enhancing technologies. This approach maintains performance leadership while ensuring compliance with evolving legal requirements.

Electric motorcycle technology represents both threat and opportunity for traditional engine manufacturers. As manufacturers introduce electric models, demand for high-displacement gasoline engines may decline. However, internal combustion motorcycles will likely remain popular for decades, particularly among enthusiasts valuing traditional riding experiences. S&S’s strategy involves maintaining leadership in traditional engine markets while exploring potential opportunities in electric drivetrain components or hybrid powerplant systems.

The company’s approach to business sustainability emphasizes maintaining market relevance through continuous innovation and strategic adaptation. Rather than resisting technological change, S&S positions itself as a leader in performance engineering regardless of propulsion technology. This mindset enables the company to preserve competitive advantages while adapting to industry evolution.

Manufacturing investment remains critical to S&S’s future competitiveness. The company continues upgrading facilities with advanced machining technology, quality control systems, and production efficiency improvements. These investments increase manufacturing capacity while maintaining the precision and quality standards that define S&S products. Investment in skilled workforce development ensures the company retains technical talent required for complex engineering and manufacturing operations.

Market expansion opportunities exist in emerging economies where motorcycle transportation remains dominant and performance customization represents growing consumer demand. S&S’s established reputation and technical capabilities position the company to capture market share in regions where motorcycles serve primary transportation functions rather than leisure purposes. Strategic partnerships with regional distributors and manufacturers can accelerate market entry and localization efforts.

Conducting a comprehensive SWOT analysis reveals that S&S possesses substantial strengths (brand recognition, engineering capability, manufacturing excellence) and opportunities (market expansion, technology integration, partnership development) that can offset potential weaknesses and threats. This balanced strategic position suggests the company is well-positioned for sustained success if management executes effectively on identified growth initiatives.

FAQ

What makes S&S motorcycle engines superior to competitor offerings?

S&S engines combine advanced engineering design, premium materials, precision manufacturing, and rigorous quality control that collectively deliver superior performance and reliability. The company’s investment in research and development, testing facilities, and technical talent enables continuous innovation that maintains performance leadership. Additionally, S&S’s brand reputation and industry partnerships validate engineering excellence and provide confidence to customers.

How do S&S engines perform in real-world riding conditions?

S&S engines are engineered and tested extensively to perform reliably across diverse riding conditions, altitudes, temperatures, and fuel quality variations. Every engine receives dyno testing and cold-start validation before shipment. Customer testimonials and professional racing success demonstrate that S&S engines deliver consistent, reliable performance in practical applications rather than merely theoretical specifications.

What is the warranty coverage for S&S engines?

S&S Cycle provides comprehensive warranty coverage protecting against manufacturing defects and material failures. Specific warranty terms vary by product type and application. Customers should review warranty documentation and consult with S&S technical staff regarding coverage details for their specific engine configuration. The company stands behind its products with warranty terms reflecting confidence in manufacturing quality and engineering reliability.

How does S&S support builders and enthusiasts during engine installation?

S&S maintains experienced technical staff available via phone, email, and online resources to provide installation guidance, troubleshooting support, and performance optimization assistance. The company provides comprehensive documentation, technical bulletins, and installation guides for every engine platform. Additionally, S&S sponsors events, participates in builder networks, and maintains active social media presence that facilitates community engagement and knowledge sharing.

What are the displacement and horsepower options available from S&S?

S&S offers engine platforms spanning approximately 88 to 128+ cubic inches of displacement, with horsepower ranging from modest increases suitable for stock motorcycle frames to extreme performance applications exceeding 200 horsepower. The company’s tiered portfolio enables customers to select solutions matching their specific performance objectives, budget constraints, and installation requirements. Detailed specifications and dyno data are available for every engine configuration.

How does S&S balance performance with fuel efficiency and reliability?

S&S engineers design engines that maximize performance while maintaining acceptable fuel consumption and reliability. Advanced fuel injection systems optimize air-fuel ratios across the operating range, improving efficiency. Precision manufacturing tolerances and premium materials ensure durability under high-performance conditions. This balanced engineering approach reflects understanding that customers value performance without sacrificing reliability or practical usability.

What role do partnerships with manufacturers play in S&S’s business strategy?

OEM partnerships provide S&S with stable revenue foundations, market validation of engineering excellence, and valuable feedback about customer preferences and industry trends. These relationships demonstrate that major manufacturers trust S&S technology for production models, communicating superior engineering to the broader market. Partnerships also provide opportunities for collaborative development and integrated supply chain management that strengthen competitive positions for both parties.