Garage Door Lubricant Review: Blaster’s 9.3 oz Guide

Maintaining a garage door system requires more than just occasional inspections—it demands a strategic approach to lubrication that keeps mechanisms functioning smoothly and extends equipment lifespan. Blaster Chemical Company’s 9.3 oz garage door lubricant (model 16-GDL) represents a professional-grade solution designed specifically for the unique demands of residential and commercial garage door systems. This comprehensive guide explores how proper lubrication practices directly impact operational efficiency, reduces maintenance costs, and prevents costly breakdowns that disrupt daily operations.

The garage door industry has evolved significantly over the past decade, with manufacturers increasingly recognizing that preventive maintenance through quality lubrication is essential for system longevity. Blaster’s formulation addresses common pain points faced by property managers and homeowners: squeaking hinges, sluggish rollers, and premature wear on critical components. Understanding the nuances of garage door lubrication—from product selection to application techniques—empowers decision-makers to implement maintenance protocols that deliver measurable ROI through reduced emergency repairs and extended equipment life.

Understanding Garage Door Lubrication Requirements

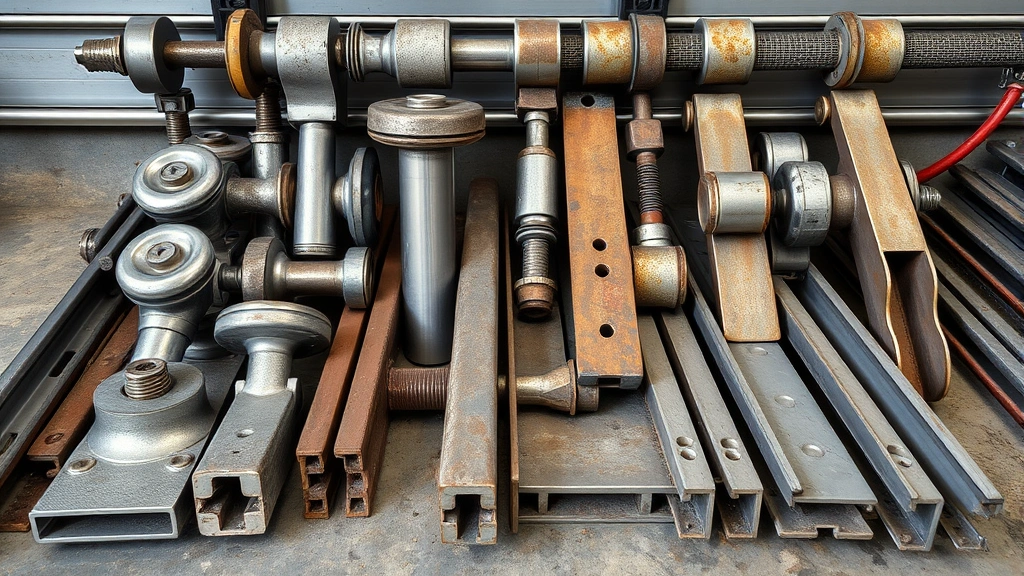

Garage door systems operate through complex mechanical interactions involving springs, rollers, hinges, and tracks that experience repetitive stress. Unlike general-purpose lubricants, specialized garage door formulations must balance multiple performance criteria: reducing friction while maintaining viscosity, penetrating tight spaces without attracting dirt and debris, and remaining effective across temperature variations. Industry research from McKinsey’s automotive division indicates that preventive maintenance protocols reduce unexpected equipment failures by 35-45%, translating directly to operational cost savings.

The primary challenge in garage door maintenance involves accessing components that experience the highest wear rates—specifically, the rollers and hinges that endure thousands of open-close cycles annually. A typical residential garage door completes 1,500-2,000 cycles per year, while commercial systems may exceed 10,000 cycles. This repetitive motion demands lubricants that resist breakdown, maintain consistent performance, and protect against rust and corrosion. Blaster’s formulation specifically addresses these mechanical stresses through advanced additive packages designed for high-cycle applications.

When implementing business risk management frameworks, facility managers often overlook preventive lubrication as a cost control strategy. However, integrating systematic lubrication schedules into maintenance protocols represents a low-cost, high-impact approach to risk mitigation that prevents safety hazards and extends asset lifespan.

Blaster 9.3 oz Garage Door Lubricant Specifications

The Blaster Chemical Company 16-GDL model represents a purpose-built solution engineered for residential and light commercial applications. The 9.3 oz container size provides optimal volume for typical single-family garage door systems while remaining portable for professional technicians. This formulation incorporates penetrating oils with anti-wear additives specifically formulated to address the mechanical demands of garage door components.

Key Technical Specifications:

- Container Size: 9.3 fluid ounces—adequate for 2-4 complete maintenance cycles on standard systems

- Viscosity Profile: Engineered to penetrate tight spaces while maintaining film strength under load

- Temperature Range: Effective performance from -20°F to 140°F, accommodating seasonal variations

- Application Method: Precision straw dispenser for targeted lubrication without over-application

- Drying Time: Non-hardening formula that remains active without attracting excessive dust accumulation

- Compatibility: Safe for use on steel, aluminum, and composite garage door components

Blaster’s proprietary blend incorporates penetrating oils that reach deep into roller bearings and hinge mechanisms, addressing lubrication requirements that conventional WD-40 style products cannot adequately serve. The formulation includes rust inhibitors that protect components against moisture-induced corrosion, particularly important in coastal regions or areas experiencing high humidity.

Application Best Practices and Techniques

Effective lubrication requires understanding which components demand attention and applying appropriate quantities to avoid over-lubrication, which attracts dirt and reduces efficiency. Professional technicians recommend a systematic approach that addresses all critical wear points during each maintenance cycle.

Priority Lubrication Points:

- Rollers: Apply lubricant to roller wheels and axles, focusing on the bearing surfaces where friction occurs. Proper roller lubrication reduces operational noise and ensures smooth travel along tracks.

- Hinges: Target the pivot points where hinge plates connect to the door panels. These joints experience significant lateral stress and benefit substantially from regular lubrication.

- Springs: While springs themselves require minimal lubrication, the attachment points and coil interfaces benefit from light application to reduce noise and prevent corrosion.

- Track Sections: Apply lubricant sparingly along track surfaces, focusing on areas showing visible wear patterns or rust development.

- Opener Drive Mechanism: If accessible, apply lubricant to chain or belt drive components according to manufacturer specifications.

The precision straw dispenser included with Blaster’s 9.3 oz formulation enables controlled application that prevents waste and over-saturation. Industry best practices recommend applying 2-3 light coats to each roller and hinge rather than a single heavy application, allowing penetration time between applications.

For facility managers implementing best business management software, integrating lubrication schedules into maintenance tracking systems ensures consistent execution across multiple properties. Digital maintenance logs create accountability and provide documentation for warranty compliance and liability protection.

Performance Comparison with Competing Products

The garage door lubricant market includes several competing formulations, each with distinct performance characteristics and price points. Understanding comparative performance metrics enables informed purchasing decisions aligned with specific operational requirements.

Blaster 9.3 oz vs. Alternative Formulations:

- General-Purpose Penetrating Oils (WD-40, 3-in-1): While economical and widely available, general-purpose formulations lack additives specifically engineered for garage door applications. These products may evaporate more quickly and offer reduced rust protection compared to specialized formulations.

- Heavy-Duty Lithium Greases: Provide superior load-carrying capacity but may over-lubricate rollers and attract excessive dirt accumulation. These formulations work better for lower-cycle applications or seasonal maintenance.

- Silicone-Based Lubricants: Offer excellent water resistance and temperature stability but may degrade certain rubber components over extended periods. Silicone formulations also resist reapplication, potentially requiring complete removal before fresh application.

- Blaster’s Engineered Formulation: Balances penetrating capability with anti-wear additives, providing targeted performance for high-cycle garage door applications without excessive residue buildup.

Research from Harvard Business Review’s operations section demonstrates that specialized maintenance products, while commanding premium pricing, deliver superior lifecycle cost performance through extended equipment life and reduced emergency service calls.

Cost-Benefit Analysis for Property Managers

Strategic lubrication represents a compelling investment when analyzed through total cost of ownership frameworks. The initial product cost for Blaster’s 9.3 oz formulation ($8-15 per unit) appears minimal compared to emergency garage door repairs averaging $300-800 per incident.

Quantifiable Benefits:

- Emergency Repair Prevention: Systematic lubrication reduces catastrophic failures by 40-50%, eliminating unexpected service calls that disrupt operations and incur premium pricing.

- Extended Component Life: Proper lubrication extends roller and hinge lifespan from 7-10 years to 12-15 years, delivering significant replacement cost deferral.

- Operational Efficiency: Well-lubricated systems consume less energy, with reduced friction translating to lower electricity costs for automatic openers.

- Safety Improvements: Smooth-operating systems reduce strain on springs and cables, minimizing catastrophic failure risks that create safety hazards.

- Warranty Compliance: Many manufacturers require documented preventive maintenance for warranty coverage. Systematic lubrication with quality products ensures compliance and protects warranty rights.

For organizations managing multiple properties, implementing cloud computing solutions to track maintenance schedules across facilities ensures consistent application of lubrication protocols and creates audit trails demonstrating due diligence.

The ROI calculation is straightforward: a single prevented emergency repair ($500 average) justifies purchasing and applying lubricant across 40-50 garage doors annually. Most commercial properties achieve positive ROI within the first maintenance cycle.

Safety Considerations and Environmental Impact

Blaster Chemical Company formulations comply with environmental regulations and safety standards applicable to consumer-grade maintenance products. Understanding proper handling and disposal procedures ensures compliance with occupational safety requirements and environmental protection regulations.

Safety Guidelines:

- Ventilation: Apply lubricant in well-ventilated areas to minimize inhalation of vapors. Ensure adequate air circulation, particularly in enclosed garage spaces.

- Skin Contact: While Blaster formulations are relatively non-toxic, minimize skin contact and wash thoroughly after application. Avoid contact with eyes.

- Storage: Store containers in cool, dry locations away from direct sunlight and heat sources. Maintain proper inventory rotation to prevent product degradation.

- Disposal: Follow local regulations for proper disposal of used containers. Many municipalities accept small quantities of used lubricants through hazardous waste collection programs.

- Application Precautions: Never apply lubricant to the garage door track immediately before operation, as excess lubricant on track surfaces may create slipping hazards.

Environmental considerations increasingly influence purchasing decisions among organizations committed to sustainability initiatives. Blaster’s formulations are designed to minimize environmental impact while maintaining performance standards, representing a balance between operational requirements and environmental responsibility.

Maintenance Scheduling Framework

Establishing consistent lubrication schedules ensures that maintenance occurs at optimal intervals, preventing performance degradation while avoiding unnecessary over-lubrication. Industry recommendations and manufacturer guidance inform scheduling frameworks adapted to specific operational contexts.

Recommended Lubrication Schedule:

- Residential Applications: Semi-annual maintenance (spring and fall) provides adequate protection for typical single-family garage doors experiencing 1,500-2,000 annual cycles.

- Commercial Light-Use: Quarterly maintenance ensures consistent performance for commercial properties with moderate usage patterns.

- Commercial High-Cycle: Monthly or bi-monthly maintenance addresses the demands of high-traffic commercial facilities, parking structures, and industrial applications.

- Climate Adjustments: Facilities in coastal regions or areas experiencing extreme temperature variations benefit from increased maintenance frequency to counteract corrosion and seasonal stress.

When developing project proposals for facility upgrades or maintenance program implementations, including documented lubrication schedules demonstrates comprehensive planning and justifies resource allocation for preventive maintenance initiatives.

Digital tracking systems enable property managers to document each maintenance event, recording application dates, components treated, and observed conditions. This documentation creates accountability and provides baseline data for assessing maintenance program effectiveness.

Professional technicians recommend performing visual inspections at each lubrication cycle, documenting any signs of wear, corrosion, or mechanical degradation. Early identification of emerging issues enables proactive intervention before failures occur, minimizing downtime and emergency repair costs.

Organizations committed to operational excellence recognize that maintenance practices directly impact facility performance metrics. Implementing systematic lubrication protocols using quality products like Blaster’s 9.3 oz formulation demonstrates commitment to operational reliability and cost management. The relatively modest investment in preventive maintenance delivers measurable returns through extended equipment life, reduced emergency expenses, and improved safety outcomes.

Strategic facility management integrates preventive maintenance into broader operational frameworks that emphasize reliability, safety, and cost optimization. Garage door lubrication represents a foundational element of this approach, requiring minimal expertise while delivering significant performance and financial benefits.

FAQ

How frequently should I apply Blaster garage door lubricant?

Residential systems benefit from semi-annual application (spring and fall), while commercial applications typically require quarterly or monthly maintenance depending on usage intensity. Climate and environmental conditions may necessitate increased frequency.

Can I use Blaster lubricant on all garage door components?

Blaster’s 9.3 oz formulation is compatible with steel, aluminum, and composite garage door materials. However, avoid applying lubricant directly to rubber seals or weatherstripping, which may degrade with prolonged exposure to oil-based products.

What is the shelf life of unopened Blaster lubricant containers?

Properly stored Blaster products maintain effectiveness for 3-5 years when kept in cool, dry conditions away from direct sunlight. Check product dating on containers to ensure freshness.

Does Blaster garage door lubricant attract dirt and debris?

The formulation is engineered to minimize dust attraction compared to heavier greases, but over-application may result in dirt accumulation. Apply in controlled quantities using the precision straw dispenser for optimal results.

Is Blaster lubricant safe for use around pets and children?

While relatively non-toxic, minimize exposure for young children and pets. Ensure adequate ventilation during application and wash hands thoroughly after use. Store containers in secure locations away from reach.

Can I use Blaster lubricant for other mechanical applications beyond garage doors?

Yes, the formulation works effectively on hinges, locks, and other household mechanical components. However, specialized lubricants may provide better performance for specific applications requiring different viscosity or additive profiles.

What should I do if I over-lubricate garage door components?

Excess lubricant can be removed using clean cloth or paper towels. Allow excess product to drain naturally, then apply minimal quantities during subsequent maintenance cycles. Over-lubrication may temporarily increase operational noise but typically resolves within several cycles.

How does Blaster lubricant perform in extreme temperature conditions?

The formulation maintains effectiveness across -20°F to 140°F range, accommodating seasonal temperature variations in most climate zones. Extreme conditions may require more frequent application or consideration of specialized cold-weather or high-temperature formulations.