Cornell Pump’s Innovations: Industry Analysis & Strategic Impact

Cornell Pump Company has established itself as a significant player in the industrial pumping solutions sector, delivering engineered systems that serve critical infrastructure, manufacturing, and commercial applications across North America. With decades of operational history, Cornell has continuously evolved its product portfolio to address emerging market demands, regulatory requirements, and technological advancements. This comprehensive analysis examines the company’s innovation trajectory, competitive positioning, and strategic initiatives that have shaped the modern pump manufacturing landscape.

The industrial pump market represents a multi-billion-dollar sector characterized by intense competition, rapid technological change, and increasing pressure for energy efficiency and sustainability. Cornell Pump Company navigates this complex environment through strategic product development, customer-centric engineering solutions, and operational excellence. Understanding Cornell’s approach to innovation provides valuable insights into how established industrial manufacturers maintain relevance and drive growth in a traditionally mature industry.

Cornell Pump Company Overview & Market Position

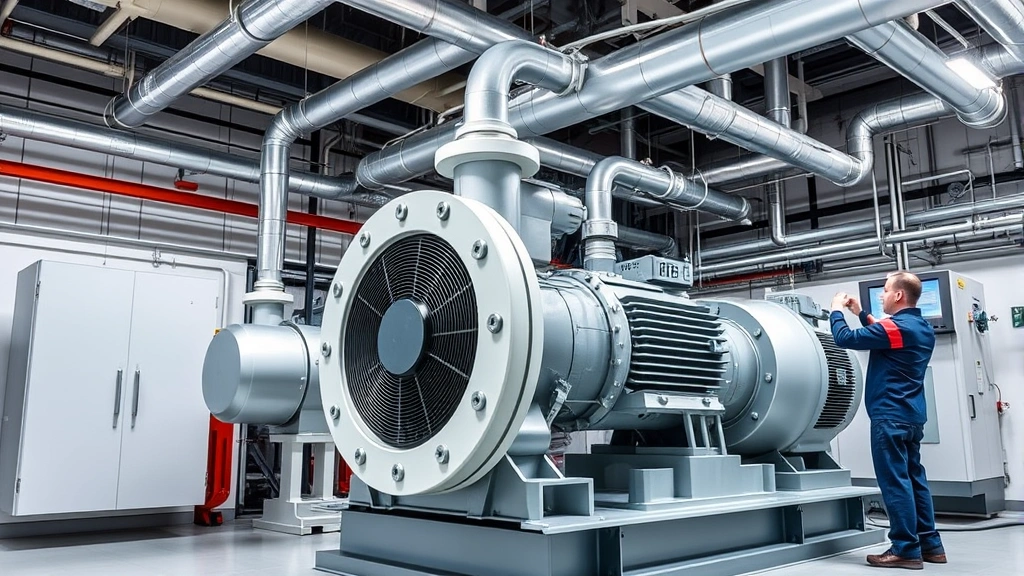

Cornell Pump Company operates within the industrial equipment manufacturing sector, specifically focusing on centrifugal and positive displacement pump systems. The company’s market position reflects its ability to serve diverse customer segments including municipal water systems, commercial HVAC applications, industrial process systems, and specialized manufacturing operations. This diversification strategy reduces dependency on any single market segment while enabling cross-pollination of technical expertise across applications.

The company’s competitive advantage stems from several interconnected factors: technical expertise developed over decades of operations, established relationships with major equipment distributors and end-users, manufacturing facilities equipped for both standard and custom solutions, and a workforce possessing deep domain knowledge in fluid dynamics and system design. These capabilities position Cornell favorably against both established competitors and emerging manufacturers attempting to capture market share through low-cost strategies.

Market analysis indicates that the industrial pump sector experiences steady demand driven by infrastructure maintenance, facility upgrades, and new construction projects. Commercial property management companies increasingly specify Cornell equipment for building systems requiring reliable performance and minimal maintenance downtime. The company’s reputation for durability and service support creates significant switching costs that protect market share and enable premium pricing strategies.

Core Product Innovation Strategy

Cornell’s innovation strategy emphasizes practical engineering improvements rather than radical redesigns, reflecting the conservative nature of industrial equipment markets where reliability supersedes cutting-edge features. The company systematically analyzes customer feedback, field performance data, and emerging application requirements to identify improvement opportunities that deliver measurable value propositions.

Recent product development initiatives have focused on several key areas:

- Enhanced Material Science: Introduction of advanced alloy compositions and coating technologies that extend equipment lifespan in corrosive environments, reducing total cost of ownership for customers operating in demanding conditions

- Hydraulic Optimization: Refined impeller designs and internal passages that improve efficiency ratings, directly translating to reduced energy consumption and operational cost savings

- Modular Architecture: Standardized component interfaces enabling rapid customization and reduced lead times for specialized applications while maintaining manufacturing efficiency

- Seal Improvements: Advanced mechanical seal designs reducing leakage and maintenance requirements, addressing a persistent pain point in customer operations

The company invests approximately 3-5% of annual revenue in research and development activities, supporting a dedicated engineering team focused on understanding emerging customer needs. This commitment reflects Cornell’s philosophy that continuous improvement drives long-term competitiveness. Unlike capital-intensive disruption strategies, incremental innovation allows the company to maintain profitability while steadily enhancing product performance.

Technology Integration & Digital Transformation

Cornell Pump Company has progressively integrated digital technologies into both product offerings and operational processes. Remote monitoring capabilities embedded in modern pump systems enable predictive maintenance, allowing customers to schedule service interventions before catastrophic failures occur. This shift from reactive to proactive maintenance represents a fundamental value proposition change that strengthens customer relationships and generates recurring revenue opportunities.

Digital transformation extends beyond product features into business operations. The company has implemented advanced business budgeting software systems that optimize resource allocation across manufacturing facilities, research initiatives, and market development activities. Enhanced data analytics capabilities provide real-time visibility into production efficiency, quality metrics, and customer satisfaction indicators.

IoT-enabled pump systems generate valuable operational data that Cornell can analyze to identify design optimization opportunities, predict maintenance needs, and develop targeted customer communications. This data-driven approach transforms Cornell from a pure equipment manufacturer into a solutions provider capable of delivering comprehensive system performance insights. Customers increasingly value these analytics capabilities as they support facility optimization and energy management objectives.

The company’s digital initiatives also extend to customer engagement platforms, enabling streamlined ordering, technical specification development, and warranty management. These digital touchpoints reduce friction in customer interactions while providing Cornell with detailed market intelligence regarding application trends and customer preferences.

Sustainability & Energy Efficiency Innovations

Environmental regulations and corporate sustainability commitments have created powerful market drivers for energy-efficient pump systems. Cornell has responded by developing product lines that significantly reduce energy consumption compared to legacy equipment. High-efficiency motor options, optimized hydraulic designs, and variable frequency drive compatibility position Cornell solutions as attractive replacements for aging infrastructure.

The company’s sustainability strategy aligns with broader industry trends emphasizing environmental responsibility. Pump systems represent substantial operational energy costs throughout their service lives—often 15-25 years—making efficiency improvements highly valuable to cost-conscious customers. A 10% efficiency improvement translates directly to proportional energy cost reductions, creating compelling financial justifications for equipment upgrades.

Cornell’s commitment to business continuity planning includes environmental risk mitigation, ensuring that manufacturing operations incorporate sustainable practices and that supply chains remain resilient against climate-related disruptions. This forward-thinking approach positions the company favorably as regulatory requirements continue tightening and customer expectations evolve.

Product lifecycle considerations influence design decisions, with Cornell increasingly utilizing materials and manufacturing processes that minimize environmental impact. End-of-life recycling programs and take-back initiatives demonstrate commitment to circular economy principles, appealing to environmentally conscious customers and differentiating Cornell from competitors with less comprehensive sustainability strategies.

Competitive Landscape Analysis

The industrial pump manufacturing sector includes established competitors such as Grundfos, Xylem, Flowserve, and ITT, alongside numerous regional manufacturers and specialized niche players. Each competitor pursues distinct market positioning strategies, creating a complex competitive environment requiring sophisticated analysis.

Conducting a thorough SWOT analysis reveals Cornell’s strategic positioning: strengths include brand reputation, manufacturing capabilities, and technical expertise; weaknesses encompass limited global presence compared to multinational competitors and smaller research budgets; opportunities include emerging markets, specialized applications, and energy efficiency retrofits; threats encompass price competition from low-cost manufacturers and consolidation among larger competitors.

Cornell competes effectively by emphasizing customization capabilities, responsive customer service, and specialized technical support that larger competitors often cannot match efficiently. The company’s regional manufacturing footprint enables faster delivery and stronger relationships with local distributors and end-users. This localized approach creates competitive advantages in markets where delivery speed and personalized engineering support drive purchasing decisions.

Industry consolidation trends present both challenges and opportunities. Larger competitors increasingly pursue acquisition strategies to expand product portfolios and market reach, potentially creating partnerships or acquisition scenarios for mid-sized manufacturers like Cornell. The company’s strong operational performance and customer relationships make it an attractive acquisition target, though independence enables strategic flexibility and decision-making speed.

Supply Chain & Manufacturing Excellence

Cornell’s manufacturing operations reflect commitment to quality, efficiency, and flexibility. The company operates multiple production facilities strategically located to serve key customer markets while maintaining cost competitiveness. Advanced manufacturing technologies including CNC machining, precision casting, and automated assembly systems enable consistent quality while reducing production costs.

Supply chain resilience has become increasingly critical following pandemic-related disruptions that exposed vulnerabilities in global manufacturing networks. Cornell has implemented diversified supplier relationships, inventory management strategies, and nearshoring initiatives that reduce dependence on distant suppliers while maintaining cost efficiency. These investments in supply chain robustness provide competitive advantages during periods of market disruption.

Quality control processes incorporate multiple verification stages, from incoming material inspection through final performance testing. Statistical process control methodologies identify trending issues before they impact customer deliveries, maintaining Cornell’s reputation for reliability. Continuous improvement initiatives driven by lean manufacturing principles reduce waste, improve throughput, and enhance profitability while maintaining product quality.

Customer Solutions & Market Applications

Cornell serves diverse customer segments through tailored solutions addressing specific application requirements. Municipal water utilities represent a significant market segment requiring large-capacity, high-reliability systems capable of operating continuously with minimal downtime. Commercial HVAC applications demand compact, efficient designs compatible with building system constraints. Industrial process applications often require specialized materials, configurations, and performance characteristics.

This market diversity requires sophisticated customer engagement capabilities and deep application knowledge. Cornell’s technical sales teams work collaboratively with engineers and facility managers to develop optimized solutions addressing specific operational challenges. This consultative approach differentiates Cornell from competitors offering standardized products with minimal customization.

Implementing effective business online marketing strategies has become essential for reaching diverse customer segments. Cornell maintains comprehensive digital resources including technical documentation, application case studies, and performance calculators that support customer decision-making processes. Content marketing initiatives demonstrate technical expertise while building brand authority within target markets.

Building business networking strategies through industry associations, trade shows, and distributor relationships strengthens market presence and generates qualified sales opportunities. These relationship-based approaches create durable competitive advantages in B2B industrial markets where trust and technical credibility significantly influence purchasing decisions.

The company’s approach to customer solutions extends beyond initial equipment sales into ongoing support relationships. Technical training programs, preventive maintenance recommendations, and retrofit consulting services create touchpoints throughout customer equipment lifecycles. These extended relationships generate recurring revenue while deepening customer loyalty and creating barriers to competitive displacement.

Performance guarantees and service level agreements demonstrate Cornell’s confidence in product quality while providing customers with risk mitigation. These contractual commitments differentiate Cornell from competitors offering standard warranties, appealing to customers operating mission-critical systems where downtime carries significant operational and financial consequences.

Strategic partnerships with complementary service providers—including installation contractors, maintenance companies, and system integrators—expand Cornell’s market reach while enhancing customer value propositions. These ecosystem relationships enable comprehensive solutions addressing complete customer requirements rather than individual component supply.

FAQ

What types of pumps does Cornell Pump Company manufacture?

Cornell manufactures both centrifugal and positive displacement pump systems designed for diverse applications including water distribution, HVAC systems, industrial processes, and specialized manufacturing operations. Product lines range from standard configurations to fully customized solutions addressing unique customer requirements.

How does Cornell maintain competitive advantages in a mature market?

Cornell differentiates through technical expertise, customization capabilities, responsive customer service, localized manufacturing and distribution, and continuous product improvements. The company emphasizes reliability, efficiency, and total cost of ownership rather than competing primarily on price.

What sustainability initiatives has Cornell implemented?

Cornell has developed high-efficiency product lines reducing energy consumption, implemented sustainable manufacturing practices, established end-of-life recycling programs, and incorporated environmental considerations into product design decisions. These initiatives align with regulatory requirements and customer sustainability objectives.

How does Cornell utilize digital technologies?

Digital transformation initiatives include remote monitoring capabilities in pump systems, advanced data analytics for predictive maintenance, customer engagement platforms, operational efficiency optimization, and IoT-enabled performance tracking that generates valuable market intelligence.

What external factors influence Cornell’s market opportunities?

Infrastructure investment cycles, regulatory environmental requirements, energy efficiency mandates, industrial production trends, commercial real estate activity, and technological advancement all influence market demand for pump systems. Cornell positions itself to capitalize on these broader economic and regulatory trends.