Caltech Kilns: Expert Maintenance Tips for Optimal Performance

Industrial kilns represent significant capital investments for manufacturing operations, and their proper maintenance directly impacts production efficiency, product quality, and operational longevity. Caltech Company Ltd. kilns have established themselves as reliable workhorses across ceramics, materials science, and specialized manufacturing sectors. Understanding the nuances of kiln maintenance transforms facility managers from reactive troubleshooters into strategic operators who maximize equipment lifespan and minimize costly downtime.

Whether you operate a single kiln facility or manage multiple units across locations, implementing a comprehensive maintenance strategy distinguishes high-performing operations from those struggling with frequent repairs and inconsistent output. This guide explores evidence-based maintenance protocols, diagnostic techniques, and operational best practices that enable Caltech kiln operators to achieve superior reliability and performance metrics.

Understanding Your Caltech Kiln System

Caltech Company Ltd. manufactures kilns engineered for precision temperature control and consistent thermal distribution. These systems typically feature advanced insulation materials, programmable controllers, and heating elements designed for extended operational cycles. Understanding your specific kiln model’s architecture forms the foundation of effective maintenance.

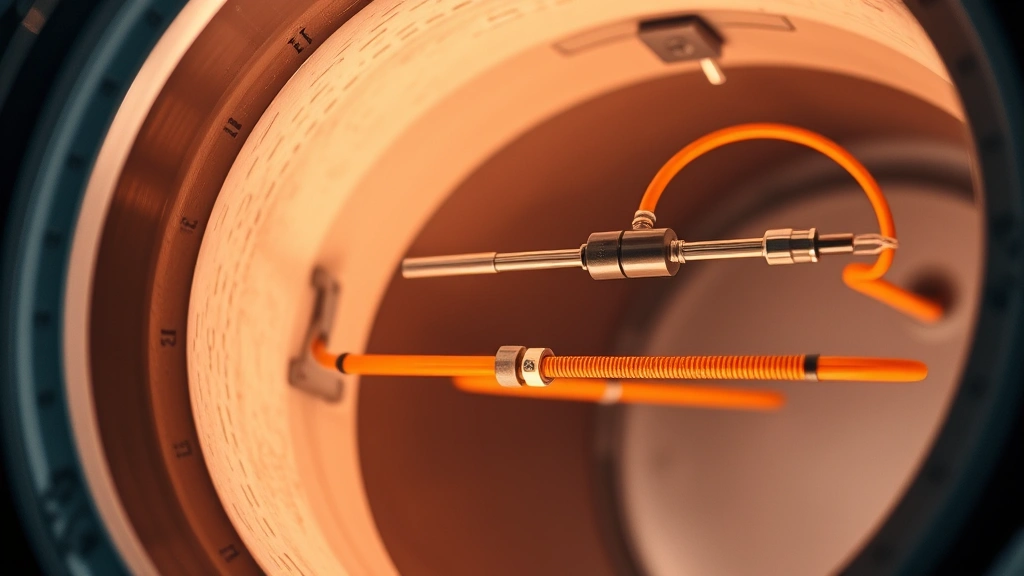

The primary components requiring attention include the heating chamber, temperature sensors, control circuitry, insulation systems, and ventilation pathways. Each element contributes to overall performance, and degradation in any single component cascades through the entire system. Regular inspection routines help identify emerging issues before they necessitate expensive repairs or production halts.

Consult your equipment documentation to understand heating element specifications, maximum operating temperatures, and ramp-rate capabilities. This information proves invaluable when diagnosing performance anomalies. If your organization operates across multiple states, maintaining detailed equipment records alongside your California company lookup or Illinois company search data helps ensure regulatory compliance and equipment documentation standards.

Daily Operational Maintenance Protocols

Successful kiln maintenance begins with daily operational vigilance. Operators should establish morning and evening inspection routines that require minimal additional time but yield substantial diagnostic benefits. These abbreviated checks identify developing problems before they escalate into serious failures.

Pre-Operation Inspections: Before activating your kiln each day, verify that temperature display readings align with room temperature, confirming sensor functionality. Inspect the chamber interior for any visible debris, unusual deposits, or structural anomalies. Ensure ventilation pathways remain unobstructed and that control panel indicators display normally. Check that all safety interlocks function properly and that emergency shutdown systems respond to test activation.

During-Operation Monitoring: As your kiln reaches operating temperature, observe heating curves and verify that temperature progression follows expected parameters. Listen for unusual sounds—grinding noises, unusual vibrations, or electrical humming—that might indicate component stress. Monitor temperature stability; excessive fluctuations suggest sensor issues or heating element degradation. Record actual operating temperatures and compare them against historical baselines to identify drift patterns.

Post-Operation Procedures: After completing firing cycles, allow appropriate cool-down periods before accessing the chamber. Document firing parameters, actual temperatures achieved, and any operational anomalies observed during the cycle. This record-keeping enables trend analysis that reveals maintenance needs before they become critical. Clean external surfaces and remove any accumulated dust from ventilation grilles.

Establishing business sustainability practices in kiln operation extends equipment life while reducing energy consumption. Proper daily maintenance aligns with broader operational excellence initiatives that enhance your facility’s competitive positioning.

Preventive Maintenance Schedules

Preventive maintenance represents the most cost-effective strategy for kiln longevity. Rather than responding to failures, systematic preventive approaches eliminate problems before they disrupt production. Industry research from Harvard Business Review demonstrates that organizations implementing structured preventive maintenance programs reduce unplanned downtime by 45% compared to reactive maintenance approaches.

Weekly Maintenance Tasks: Each week, perform detailed visual inspections of all accessible kiln components. Examine heating elements for signs of burnout, discoloration, or physical damage. Inspect insulation surfaces for cracks, spalling, or deterioration. Check electrical connections for corrosion or loosening. Clean control panel displays and verify that all indicator lights function correctly. Test temperature sensor responsiveness by introducing slight environmental changes and confirming that displayed readings adjust appropriately.

Monthly Comprehensive Reviews: Monthly maintenance sessions should include more extensive procedures. Calibrate temperature sensors against secondary measurement devices to verify accuracy. Inspect and clean ventilation systems thoroughly, removing accumulated particulates that restrict airflow and reduce cooling efficiency. Examine structural integrity of the kiln frame, checking for warping, rust development, or loose fasteners. Review operational logs to identify temperature stability trends or performance patterns suggesting component degradation.

Quarterly Deep Maintenance: Every three months, conduct thorough examinations of heating element integrity and electrical system performance. Test all safety systems comprehensively, including emergency shutoff mechanisms, over-temperature protection circuits, and interlock functionality. Inspect refractory materials systematically, documenting any observed damage or deterioration. This deeper assessment often reveals issues that daily or weekly inspections might overlook.

Annual Professional Assessment: Engage qualified technicians annually for comprehensive kiln evaluations. These professionals possess specialized equipment and expertise to assess internal conditions, heating element performance, and control system calibration with precision. Annual assessments provide baseline data that helps predict maintenance needs and optimize replacement timing for wear components.

Temperature Control and Calibration

Temperature accuracy defines kiln performance quality. Even minor calibration drift produces product inconsistencies and quality failures. Maintaining precise temperature control requires systematic calibration procedures and understanding of sensor limitations.

Thermocouple Calibration: Most Caltech kilns utilize thermocouple sensors for temperature measurement. These devices gradually drift from calibration over time, particularly in high-temperature environments. Establish quarterly calibration checks using secondary measurement methods. Infrared thermometers or calibrated thermocouple simulators provide reliable reference points. Document all calibration data, recording both measured values and adjustments applied. This historical record enables prediction of calibration intervals and identification of sensors requiring replacement.

Ramp Rate Optimization: Caltech kilns support programmable heating ramps that control temperature rise rates. Slower ramp rates reduce thermal stress on both kiln materials and product loads, extending equipment life. Faster ramps increase production throughput but accelerate component wear. Analyze your production requirements and adjust ramp rates to balance throughput needs against equipment longevity. Many facilities discover that slightly reduced ramp rates produce superior product quality while extending kiln service life significantly.

Temperature Uniformity Assessment: Interior chamber temperatures may vary across different locations, affecting product consistency. Periodically conduct multi-point temperature measurements using portable thermocouple devices. Identify hot spots or cold zones that might indicate heating element imbalances or insulation deficiencies. Temperature variations exceeding 10°C across the chamber suggest service requirements, while variations under 5°C indicate optimal performance.

Control System Updates: Modern Caltech kilns feature programmable digital controllers. Ensure that firmware remains current and that control algorithms reflect your facility’s operational requirements. Manufacturers periodically release updates improving temperature stability, energy efficiency, and diagnostic capabilities. Consult with McKinsey research on manufacturing technology optimization to understand how control system improvements impact overall facility performance.

Refractory Material Management

Refractory materials—the heat-resistant linings protecting kiln structures—represent critical maintenance considerations. These materials gradually degrade through thermal cycling, chemical attack, and physical erosion. Systematic monitoring and replacement prevent catastrophic failures.

Visual Inspection Protocols: During each monthly inspection, examine internal refractory surfaces for cracks, spalling, or material loss. Small cracks often develop into major fractures, so early detection enables planned maintenance rather than emergency repairs. Photograph identified damage areas and maintain a damage log tracking progression. If cracks expand noticeably between inspections, schedule maintenance before structural integrity becomes compromised.

Refractory Replacement Planning: Refractory materials typically require replacement every 3-5 years, depending on operating intensity and temperature extremes. Plan replacements strategically during production downtime rather than responding to emergency failures. Establish relationships with qualified refractory contractors who understand Caltech kiln specifications. Budget replacement costs as routine maintenance rather than unexpected capital expenses.

Material Selection and Quality: When replacing refractories, specify materials matched to your operating temperature range and chemical environment. High-alumina refractories work well for temperatures to 1500°C, while specialized materials suit higher temperatures or corrosive atmospheres. Selecting appropriate materials ensures longevity and prevents premature failure. Lower-cost materials may require more frequent replacement, ultimately increasing total cost of ownership.

Installation Best Practices: Proper installation proves as critical as material selection. Ensure that refractory contractors follow manufacturer specifications regarding brick arrangement, mortar composition, and curing procedures. Inadequate installation practices compromise material performance regardless of quality. Supervise installation work and verify that completed installations match specifications before returning kilns to service.

Troubleshooting Common Issues

Even with excellent preventive maintenance, operational issues occasionally emerge. Systematic troubleshooting approaches help identify root causes and determine appropriate solutions.

Temperature Reading Inconsistencies: When kiln displays show unexpected temperatures, first verify that sensor connections remain secure and that wiring shows no visible damage. Check that displayed readings align with physical chamber conditions—if the kiln appears hot but displays low temperatures, sensor failure is likely. Compare readings against backup measurement devices. Sensor replacement typically resolves these issues, though occasionally control circuit problems require professional diagnostics.

Heating Element Failure: Kilns that heat slowly or fail to reach target temperatures likely experience heating element degradation. Visually inspect elements for discoloration, cracking, or burnout. Partially failed elements often display dark spots or thin sections where material has burned away. Elements typically require replacement when visible damage appears. Attempting to extend element life beyond safe limits risks complete failure during critical production cycles.

Uneven Temperature Distribution: Interior temperature variations exceeding acceptable ranges suggest heating element imbalances, insulation deficiencies, or ventilation problems. Verify that ventilation pathways remain unobstructed and that cooling systems function properly. Check that heating elements distribute evenly around the chamber and that none have failed. Insulation damage allowing heat escape typically appears as external surface hot spots; thermal imaging helps identify these issues.

Control System Malfunctions: If the kiln responds sluggishly to temperature adjustments or displays erratic readings, control circuit issues may exist. Verify that all connections remain tight and that no visible corrosion affects terminals. Power cycle the unit to reset electronics. If problems persist, professional diagnostics likely prove necessary, as circuit board repair requires specialized expertise.

For organizations managing equipment across multiple facilities, companies that had their IPO in 2014 and similar established manufacturers often provide excellent technical support resources and spare parts availability. Establishing relationships with reliable suppliers ensures rapid access to components when troubleshooting identifies replacement needs.

Safety Considerations

Kiln operation involves significant hazards including extreme heat, electrical power, and potentially toxic fumes. Maintenance activities require strict adherence to safety protocols protecting personnel and facilities.

Electrical Safety: Before performing any electrical maintenance, disconnect power at the main breaker and verify disconnection using a voltage tester. Never assume power is off without verification. Ensure that qualified electricians perform complex electrical work. High-voltage components present electrocution risks that casual maintenance personnel should not attempt to address.

Thermal Hazards: Allow kilns to cool completely before accessing internal chambers. Even cooled kilns retain significant residual heat; use appropriate protective equipment when working in or near heated areas. Implement lockout/tagout procedures preventing accidental kiln activation during maintenance work. This simple protocol prevents severe burns and thermal injuries.

Ventilation and Fume Safety: Some materials release toxic fumes during heating. Ensure that facility ventilation systems operate properly during kiln operation. Conduct periodic air quality monitoring in areas near kilns, particularly if working with specialty materials. Provide appropriate respiratory protection when fume risks exist.

Training and Certification: Ensure that personnel performing maintenance work receive proper training and certification. Qualified technicians understand equipment-specific hazards and appropriate safety procedures. Regular safety training refreshers keep safety protocols current and reinforce hazard awareness. Document all training activities and maintain records demonstrating personnel qualifications.

Organizations seeking to understand broader safety and compliance frameworks should review how liability issues affect companies to appreciate the legal importance of maintaining safe equipment and training records.

FAQ

How often should I calibrate my Caltech kiln temperature sensors?

Temperature sensor calibration should occur quarterly as part of routine preventive maintenance. More frequent calibration may be necessary in high-use environments or when historical data indicates rapid drift. Always calibrate after major repairs or heating element replacement to ensure accuracy from the outset.

What is the typical lifespan of Caltech kiln heating elements?

Heating element lifespan varies based on operating temperature and usage intensity, typically ranging from 2-5 years. Elements operating at maximum temperature continuously wear faster than those operating at moderate temperatures with periodic high-temperature cycles. Monitor element condition regularly and plan replacements before failure occurs.

Can I repair damaged refractory materials or must they be completely replaced?

Minor damage may be repaired using refractory patches or specialized repair compounds, but extensive damage requires complete refractory replacement. Repairs provide temporary solutions extending service life, but planned replacement ultimately proves more reliable and cost-effective than attempting to maintain heavily damaged refractories.

What maintenance tasks require professional technician assistance?

Complex electrical work, control system diagnostics, professional calibration certification, refractory installation, and heating element replacement should be performed by qualified technicians. While operators can perform visual inspections and basic cleaning, specialized tasks require professional expertise and equipment.

How can I reduce kiln operating costs while maintaining performance?

Optimizing ramp rates, implementing preventive maintenance to avoid emergency repairs, ensuring proper insulation to minimize heat loss, and maintaining accurate temperature control through regular calibration all reduce operating costs. Additionally, scheduling maintenance during planned downtime rather than responding to failures minimizes production disruption and associated costs.

What should I do if my kiln displays temperature readings that don’t match actual chamber conditions?

First, verify that sensor connections are secure and undamaged. Compare displayed readings against secondary measurement devices like infrared thermometers. If discrepancies persist, the temperature sensor likely requires replacement. Professional diagnostics can confirm whether the issue involves sensor failure or control circuit problems.

Are there industry standards for kiln maintenance documentation?

While no universal standard exists, maintaining detailed logs of maintenance activities, temperature readings, repairs, and component replacements follows industry best practices. This documentation helps predict maintenance needs, supports warranty claims, and demonstrates due diligence in equipment stewardship. Digital maintenance management systems streamline documentation while enabling trend analysis.