Cazenovia Equipment: Expert Maintenance Tips for Maximum Operational Efficiency

Cazenovia Equipment Company has established itself as a trusted provider of industrial machinery and equipment solutions across multiple sectors. Proper maintenance of equipment is not merely a operational necessity—it’s a strategic investment that directly impacts profitability, safety, and longevity of assets. Organizations that prioritize systematic maintenance protocols consistently outperform competitors in downtime reduction and cost management.

Whether you operate heavy machinery, industrial processing equipment, or specialized tools, understanding maintenance best practices specific to Cazenovia equipment ensures optimal performance and extends asset lifespan significantly. This comprehensive guide provides actionable strategies that equipment managers and facility directors can implement immediately to enhance operational reliability and reduce unexpected failures.

Understanding Cazenovia Equipment Maintenance Fundamentals

Effective equipment maintenance begins with understanding the core principles that govern machinery reliability and performance. Cazenovia equipment, like all industrial systems, operates within specific parameters designed by manufacturers to ensure safety and efficiency. Deviations from these parameters—whether through inadequate lubrication, improper alignment, or component wear—accelerate degradation and create operational risks.

The foundation of any maintenance program rests on three pillars: preventive maintenance, predictive maintenance, and corrective maintenance. Preventive maintenance involves scheduled servicing based on time intervals or usage metrics. Predictive maintenance utilizes data analysis and monitoring technology to identify potential failures before they occur. Corrective maintenance addresses failures after they happen, representing the most costly approach when used exclusively.

Organizations implementing comprehensive maintenance strategies typically achieve 25-35% reductions in unplanned downtime. The investment in proactive maintenance protocols pays dividends through improved asset utilization and reduced emergency repair expenses. When considering business exit strategies, well-maintained equipment portfolios significantly enhance company valuation and attractiveness to potential buyers.

Understanding your specific Cazenovia equipment specifications is critical. Each model features unique maintenance requirements, fluid capacities, torque specifications, and service intervals. Consulting original manufacturer documentation ensures compliance with warranty provisions and optimal performance standards.

Preventive Maintenance Strategies for Equipment Longevity

Preventive maintenance represents the cornerstone of sustainable equipment management. Rather than waiting for failures to occur, systematic preventive approaches eliminate the majority of unexpected breakdowns and associated production losses. Research from McKinsey & Company indicates that organizations with mature preventive maintenance programs experience 40% fewer equipment failures compared to reactive-only approaches.

Establishing Maintenance Schedules

Create detailed maintenance calendars based on manufacturer recommendations and operational intensity. Cazenovia equipment typically requires servicing at intervals such as 250 hours, 500 hours, 1000 hours, or annually—depending on equipment classification. Document these intervals prominently and assign responsibility to specific personnel. Digital maintenance management systems automate reminders and track completion, reducing administrative overhead while improving compliance rates.

Lubrication Management

Proper lubrication prevents friction-induced wear and extends component lifespan dramatically. Establish protocols specifying:

- Correct lubricant types for each equipment component

- Application intervals and quantities

- Lubricant storage conditions and shelf-life management

- Used lubricant disposal procedures complying with environmental regulations

Many organizations overlook lubricant quality degradation. Contaminated or oxidized lubricants provide inferior protection and accelerate wear. Implement lubricant analysis programs that test viscosity, contamination levels, and additive depletion. This data-driven approach identifies degradation before it damages equipment.

Inspection and Cleaning Protocols

Regular visual inspections identify developing problems before they become critical. Train technicians to recognize warning signs including unusual vibrations, discoloration, fluid leaks, corrosion, and noise changes. Establish checklists ensuring consistent inspection quality across all personnel.

Cleanliness directly impacts equipment reliability. Dust, debris, and contaminants accumulate in cooling systems, electrical components, and mechanical assemblies, reducing efficiency and accelerating wear. Implement regular cleaning schedules using appropriate methods for each equipment type—compressed air for some applications, specialized solvents for others.

Diagnostic Tools and Monitoring Systems

Modern maintenance practices leverage advanced diagnostic technologies to provide real-time equipment health insights. Predictive maintenance systems analyze multiple data streams simultaneously, identifying anomalies that precede failures by days or weeks.

Vibration Analysis

Vibration signatures reveal bearing wear, misalignment, imbalance, and looseness. Portable vibration meters measure equipment vibration across frequency ranges, with abnormal patterns indicating specific failure modes. Trending vibration data over time enables technicians to schedule maintenance before catastrophic failure occurs. This technology proves particularly valuable for rotating equipment common in industrial settings.

Thermal Imaging

Infrared thermography detects temperature anomalies indicating electrical faults, bearing friction, or cooling system failures. Loose electrical connections generate excessive heat. Bearing degradation increases friction and temperature. Regular thermal imaging surveys identify hotspots requiring immediate attention before equipment failure.

Ultrasound Detection

Ultrasonic technology identifies high-frequency sounds associated with electrical arcing, steam leaks, and bearing defects. These sounds often precede visible failure indicators by significant periods, providing early warning capabilities unavailable through conventional inspection methods.

Oil Analysis Programs

Laboratory analysis of equipment fluids reveals internal wear patterns, contamination levels, and additive depletion. Ferrous content indicates metal wear, while silicon contamination suggests seal failures or inadequate air filtration. Trending oil analysis results provides predictive insights enabling preventive maintenance scheduling.

Common Maintenance Issues and Solutions

Understanding prevalent Cazenovia equipment failure modes enables proactive mitigation. Industry experience identifies recurring problems affecting equipment reliability across different operational environments.

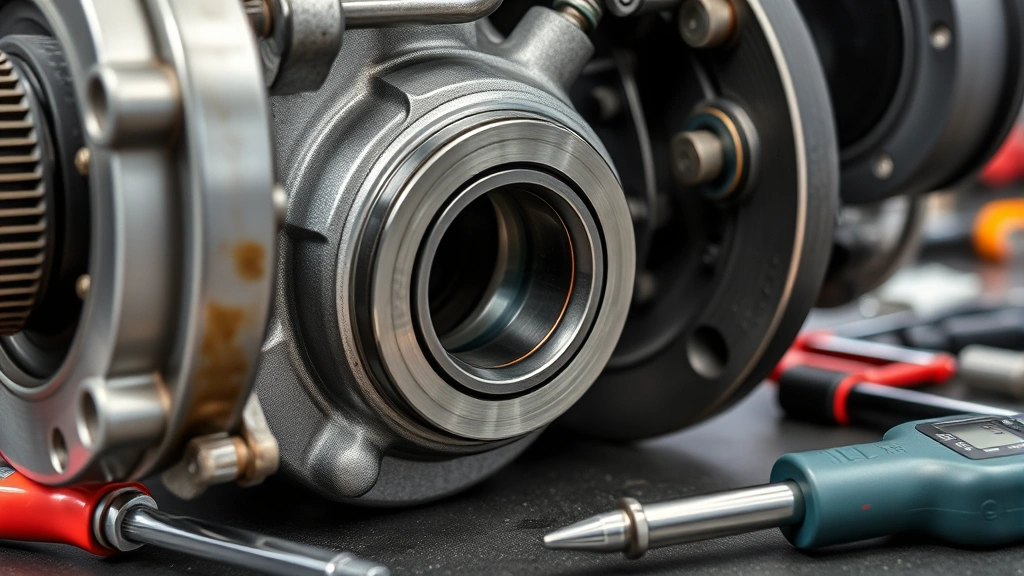

Bearing Failures and Prevention

Bearing failures represent the most common equipment issue, typically resulting from inadequate lubrication, contamination, misalignment, or overload conditions. Prevention strategies include:

- Maintaining proper lubrication intervals with appropriate lubricant types

- Implementing effective sealing systems preventing contaminant ingress

- Ensuring proper shaft alignment during installation and maintenance

- Monitoring bearing temperature and vibration signatures

- Replacing bearings before wear reaches critical thresholds

Seal and Gasket Deterioration

Seals and gaskets degrade through exposure to temperature extremes, chemical solvents, and mechanical stress. Regular inspection identifies hardening, cracking, or permanent deformation. Maintain replacement seal inventories to minimize emergency repair delays. When replacing seals, ensure cleanliness during installation—even microscopic particles compromise seal integrity.

Corrosion and Rust Prevention

Environmental exposure causes surface and internal corrosion reducing equipment lifespan and aesthetic appeal. Implement protective coatings appropriate for your operational environment. For equipment stored outdoors or in corrosive atmospheres, apply additional protection such as rust inhibitor oils or protective coverings. When considering business partnership agreements involving equipment leasing or shared assets, clearly define responsibility for corrosion prevention and remediation.

Electrical Component Failures

Moisture, dust, and vibration compromise electrical connections and component integrity. Implement regular electrical inspections checking for loose connections, corrosion on terminals, and proper grounding. Thermal imaging identifies overheating electrical components before failure occurs. Ensure proper ventilation around electrical enclosures preventing moisture accumulation.

Documentation and Record-Keeping Best Practices

Comprehensive maintenance documentation creates institutional knowledge, supports compliance audits, and enables data-driven decision-making. Organizations with mature documentation practices significantly improve maintenance effectiveness and equipment reliability.

Maintenance Log Systems

Maintain detailed records for each piece of Cazenovia equipment documenting:

- Service dates and intervals completed

- Technician names and qualifications

- Specific work performed with parts replaced

- Equipment condition observations

- Diagnostic test results and measurements

- Recommendations for future maintenance

- Associated costs and labor hours

Digital maintenance management systems provide superior organization compared to paper logs. Cloud-based platforms enable multi-location access, automated reporting, and integration with inventory and accounting systems. These systems generate valuable analytics identifying maintenance trends and cost optimization opportunities.

Parts Inventory Management

Maintain adequate inventories of common replacement parts—seals, filters, bearings, and fasteners—reducing emergency repair delays. However, excess inventory ties up capital and occupies storage space. Implement inventory management systems tracking part usage patterns and optimizing stock levels. Establish relationships with trusted suppliers capable of expedited delivery for critical components.

Historical Analysis and Trending

Analyze maintenance data identifying recurring issues, seasonal patterns, and equipment-specific vulnerabilities. Equipment experiencing frequent failures may require replacement or major refurbishment. Trending data supports capital budgeting decisions and operational planning. When exploring emerging technologies in equipment management, data analytics capabilities should be primary evaluation criteria.

Staff Training and Competency Development

Equipment maintenance quality directly correlates with technician knowledge and skill levels. Investing in comprehensive training programs ensures consistent maintenance standards and reduces human-error-related failures.

Technician Certification Programs

Enroll maintenance personnel in manufacturer-specific training and industry certification programs. Cazenovia equipment manufacturers often provide technical training ensuring technicians understand equipment-specific maintenance requirements, proper procedures, and safety protocols. Industry certifications such as those offered through professional associations validate competency and improve employee retention.

Safety Training and Protocols

Equipment maintenance involves inherent hazards including lockout-tagout procedures, electrical safety, chemical exposure, and mechanical risks. Implement mandatory safety training ensuring all technicians understand hazard identification, proper protective equipment, and emergency procedures. Regular safety refresher training maintains awareness and reinforces proper practices.

Knowledge Transfer and Documentation

Experienced technicians possess valuable institutional knowledge often undocumented and at risk when personnel transitions occur. Implement formal knowledge transfer programs capturing expertise through documented procedures, video tutorials, and mentorship programs. This approach preserves critical knowledge and accelerates new technician competency development.

Cross-Training Initiatives

Develop technicians capable of servicing multiple equipment types and systems. Cross-training improves operational flexibility, reduces single-point-of-failure dependencies, and enhances career development opportunities—improving retention. Structure training progressively from basic competencies to advanced specializations.

FAQ

What maintenance interval should I follow for Cazenovia equipment?

Maintenance intervals vary by equipment model and operational intensity. Consult your equipment manual for manufacturer-recommended intervals, typically ranging from 250 to 1000 operating hours or annually. Track actual usage and adjust intervals based on operational conditions—equipment used in harsh environments may require more frequent service than those in controlled settings.

How can I reduce unexpected equipment downtime?

Implement preventive maintenance schedules, establish predictive monitoring systems, and maintain adequate spare parts inventory. Train technicians thoroughly and document all maintenance activities. These combined approaches reduce unplanned downtime by 25-40% based on industry benchmarks. Additionally, develop contingency plans identifying backup equipment or alternative processes for critical systems.

What is the difference between preventive and predictive maintenance?

Preventive maintenance occurs on fixed schedules regardless of equipment condition. Predictive maintenance uses monitoring data and diagnostics to determine actual maintenance needs, servicing equipment only when indicators suggest imminent failure. Predictive approaches reduce unnecessary servicing while preventing failures, providing superior cost-effectiveness for organizations with mature monitoring capabilities.

How should I store Cazenovia equipment during extended idle periods?

Before storing equipment, perform comprehensive maintenance including fluid changes, lubrication application, and corrosion protection. Drain fuel from gasoline engines and stabilize fuel systems. Cover equipment protecting from dust and environmental exposure. Store in climate-controlled facilities when possible. Periodically operate equipment during extended storage preventing seal degradation and component seizing.

What documentation should I maintain for compliance and warranty purposes?

Maintain complete maintenance records documenting service dates, work performed, parts replaced, technician identifications, and diagnostic findings. Keep original equipment documentation, warranty cards, and manufacturer communications. This documentation supports warranty claims, demonstrates due diligence in maintenance, and provides valuable information for equipment resale or disposition decisions.

How do I identify when equipment requires replacement versus repair?

Evaluate replacement versus repair decisions considering equipment age, repair costs relative to replacement cost, operational reliability trends, and technological advancements. Generally, if repair costs exceed 50% of replacement value or equipment experiences frequent failures, replacement becomes economically preferable. Consider operational requirements—newer equipment may offer efficiency improvements justifying replacement beyond pure cost analysis.