Ash Grove Cement’s Market Impact: A Comprehensive Industry Analysis

Ash Grove Cement Company stands as one of North America’s most significant cement producers, wielding considerable influence over the construction materials market. With operations spanning multiple states and a production capacity that serves millions of construction projects annually, this organization has fundamentally shaped how the cement industry operates. Understanding Ash Grove’s market position provides critical insights into broader trends affecting infrastructure development, sustainable manufacturing, and competitive dynamics within the building materials sector.

The cement industry represents a cornerstone of modern infrastructure, yet it remains largely invisible to consumers who encounter concrete in roads, buildings, and bridges daily. Ash Grove Cement’s strategic positioning within this market reveals important lessons about operational excellence, regional dominance, and the challenges facing traditional heavy manufacturing in an increasingly competitive global landscape.

Company Overview and Market Position

Ash Grove Cement Company has maintained operations since 1892, establishing itself as a legacy player within the American cement manufacturing sector. The company operates as a major subsidiary within the broader building materials industry, competing directly with giants like Lafarge, Essroc, and other regional producers. Ash Grove’s market impact extends beyond simple production volumes; the organization influences pricing structures, technological standards, and sustainability practices across the entire North American cement market.

The company’s strategic importance stems from its geographic distribution and production efficiency. Unlike smaller regional competitors, Ash Grove possesses the scale necessary to influence market dynamics while maintaining the operational flexibility to serve diverse customer segments. This dual capability—massive scale combined with regional responsiveness—has proven invaluable in an industry where transportation costs significantly impact final product pricing and availability.

When examining how companies maintain competitive advantages, understanding business structure advantages becomes relevant even for large manufacturers. While Ash Grove operates as a corporate entity rather than a sole proprietorship, the principles of operational efficiency and focused strategy apply universally across business models.

Production Capacity and Geographic Reach

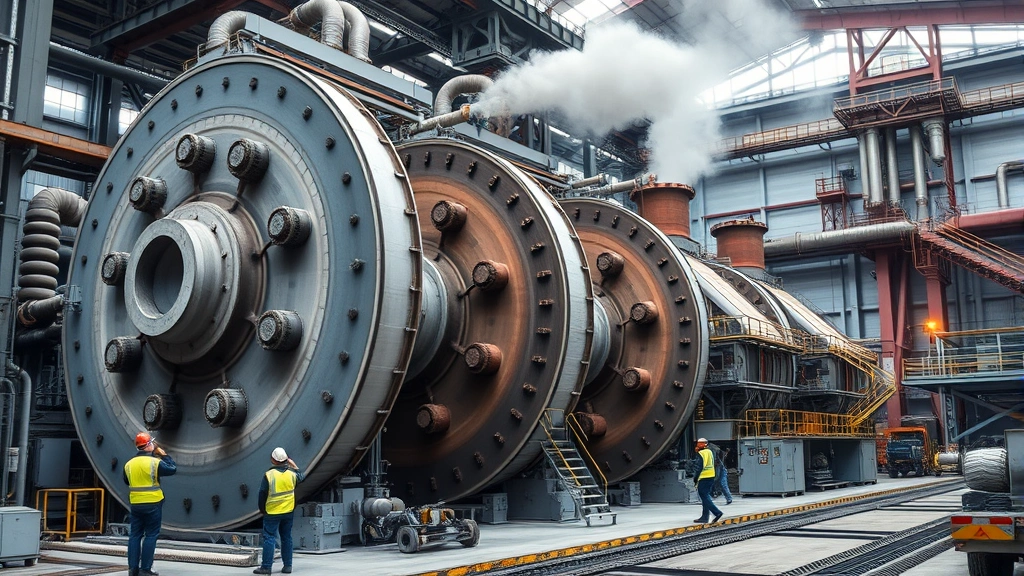

Ash Grove Cement operates multiple cement plants strategically positioned throughout the United States, with facilities in Kansas, Missouri, Colorado, and California. This geographic distribution serves a critical function: it reduces transportation costs while ensuring reliable supply to regional construction markets. The company’s production capacity exceeds several million tons annually, positioning it among North America’s top cement manufacturers.

The distribution network extends beyond manufacturing facilities to include distribution terminals, ready-mix concrete operations, and partnerships with construction material suppliers. This vertical integration strategy mirrors approaches used by businesses implementing process automation, where streamlined operations reduce inefficiencies and improve margins. Ash Grove’s integrated model allows the company to capture value at multiple points along the supply chain, from raw material extraction through final product delivery.

Geographic positioning creates significant competitive advantages. Cement’s weight and bulk make transportation expensive, effectively creating regional markets. Ash Grove’s multi-plant strategy ensures the company can serve customers across multiple regions economically, whereas competitors with single or limited facilities face higher logistics costs that compress margins or force price increases.

Competitive Landscape Analysis

The North American cement market consists of approximately a dozen major producers competing for market share in a relatively mature industry. According to McKinsey’s analysis of materials competition, producers compete primarily on cost efficiency, geographic reach, and product consistency rather than product differentiation. Ash Grove competes effectively across all these dimensions.

Lafarge and Essroc represent the primary direct competitors, each controlling significant market share in overlapping regions. However, Ash Grove’s focused strategy on premium market segments and operational efficiency has enabled the company to maintain healthy margins despite intense price competition. The company’s emphasis on customer service and technical support provides differentiation in what might otherwise be a commodity market.

Market consolidation remains an ongoing trend in cement manufacturing. Larger competitors continuously acquire smaller regional players, creating scale advantages that smaller producers struggle to match. Ash Grove’s size positions it safely above the acquisition threshold while remaining small enough to maintain operational agility. This middle-ground positioning reflects sophisticated competitive strategy—large enough to compete on cost and scale, yet nimble enough to serve specialized regional markets.

Sustainability and Environmental Impact

Cement manufacturing ranks among the most energy-intensive and carbon-emitting industrial processes. Ash Grove Cement has invested significantly in environmental improvements, including kiln optimization, alternative fuel utilization, and emissions reduction technologies. These investments reflect both regulatory pressure and market demand for sustainable building materials.

The company’s sustainability initiatives extend beyond emissions reduction. Ash Grove utilizes alternative fuels derived from waste materials, reducing landfill burden while lowering production costs. This circular economy approach aligns with broader industry trends toward environmental responsibility. Construction industry stakeholders increasingly evaluate cement suppliers based on carbon footprint and sustainability credentials, making environmental performance a competitive factor.

Regulatory frameworks continue tightening around cement manufacturing emissions. The Environmental Protection Agency and state agencies impose increasingly stringent standards on air quality and greenhouse gas emissions. Ash Grove’s proactive investments in emissions-reduction technology position the company favorably relative to competitors slower to adapt. Understanding how organizations manage regulatory compliance and operational transformation offers lessons applicable across industries, particularly for business leaders seeking guidance on navigating complex transitions.

Market Trends and Future Outlook

Several macro trends will shape Ash Grove Cement’s market position over the coming decade. Infrastructure investment in the United States, driven by government funding initiatives, creates substantial demand for cement and concrete products. The Biden administration’s infrastructure spending, combined with state and local capital projects, supports continued demand for Ash Grove’s products across multiple end markets.

However, cyclical downturns in construction pose ongoing risks. Economic recessions typically reduce commercial and residential construction activity, directly impacting cement demand. Ash Grove must maintain operational flexibility to scale production up or down in response to demand fluctuations while preserving profitability during slower periods.

Technological innovation in cement formulation presents both opportunities and threats. Development of lower-carbon cement alternatives, including blended cements and supplementary cementitious materials, could reduce demand for traditional Portland cement. Ash Grove’s investment in research and development positions the company to participate in this transition rather than be disrupted by it.

Digital transformation initiatives are reshaping how cement companies operate. Forbes reports on digital transformation in manufacturing, highlighting how automation and data analytics improve efficiency and reduce costs. Ash Grove’s modernization efforts in plant automation and supply chain optimization reflect this broader industry trend.

Supply Chain Integration

Ash Grove’s market impact extends significantly through its supply chain relationships. The company works closely with concrete producers, construction companies, and material distributors who depend on reliable cement supply. This ecosystem of relationships creates switching costs that strengthen Ash Grove’s competitive position—customers develop operational dependencies on specific suppliers’ reliability and consistency.

The company’s vertical integration strategy, combining cement production with ready-mix concrete operations and distribution capabilities, creates efficiency gains unavailable to pure-play cement manufacturers. This integrated approach mirrors principles discussed in business collaboration and operational synergy, where aligned teams working toward shared objectives generate superior results.

Supply chain resilience became critically important following pandemic-related disruptions. Ash Grove’s diversified production base and integrated distribution network proved advantageous during periods of supply chain stress. The company’s ability to redirect production between facilities and manage inventory efficiently demonstrated the value of geographic diversification and operational sophistication.

Relationships with raw material suppliers represent another critical supply chain dimension. Cement production requires limestone, silica, and other minerals available from numerous geological sources. Ash Grove’s long-term relationships with quarry operators and raw material suppliers ensure consistent access to quality inputs at competitive prices. These supplier relationships constitute valuable competitive assets not easily replicated by new entrants.

Looking at successful business communication strategies, particularly digital marketing approaches, reveals how modern companies build brand awareness. While Ash Grove primarily serves business-to-business markets, the company increasingly uses digital channels to communicate sustainability credentials and technical capabilities to specifying engineers and construction professionals.

FAQ

What is Ash Grove Cement’s primary market focus?

Ash Grove Cement primarily serves the construction industry through production and distribution of Portland cement and related products. The company focuses on regional markets in the western and central United States, where its production facilities provide cost advantages over distant competitors. Customer segments include ready-mix concrete producers, concrete product manufacturers, and construction companies requiring bulk cement supplies.

How does Ash Grove compete against larger international cement producers?

While international competitors like Lafarge and Holcim operate at larger global scales, Ash Grove’s competitive advantages derive from geographic positioning, operational efficiency, and customer intimacy. The company’s regional focus and multi-plant strategy reduce transportation costs and enable faster response to local market conditions. Additionally, Ash Grove’s emphasis on technical support and customer service provides differentiation in regional markets where relationships matter significantly.

What environmental initiatives has Ash Grove implemented?

Ash Grove has invested in multiple environmental programs including kiln efficiency improvements, alternative fuel utilization, emissions reduction technologies, and waste material incorporation into cement formulations. These initiatives reduce carbon emissions, lower production costs through waste fuel utilization, and address regulatory requirements. The company continues investing in cleaner production technologies to meet evolving environmental standards and market expectations for sustainable products.

How does cement transportation impact Ash Grove’s business model?

Transportation costs represent a significant factor in cement pricing due to the product’s weight and bulk. Ash Grove’s multi-plant strategy addresses this challenge by positioning production facilities close to major customer concentrations. This geographic distribution reduces shipping distances and costs, enabling the company to compete effectively against distant competitors while maintaining healthy margins. The company also operates distribution terminals and ready-mix concrete facilities that further reduce transportation costs for customers.

What market opportunities exist for Ash Grove in coming years?

Infrastructure investment in the United States creates substantial demand growth opportunities for cement products. Government-funded projects in roads, bridges, water systems, and public buildings will drive cement consumption. Additionally, development of lower-carbon cement products positions Ash Grove to participate in the industry’s sustainability transition. Digital transformation initiatives and automation investments offer opportunities to improve efficiency and reduce production costs, enhancing competitive positioning.

How does Ash Grove maintain product quality consistency?

Ash Grove employs rigorous quality control processes across all production facilities, utilizing standardized manufacturing procedures and modern testing equipment. The company invests in employee training and maintains consistent raw material sourcing to ensure product uniformity. Quality assurance extends beyond production to include testing at distribution terminals and customer facilities. This commitment to consistency builds customer confidence and supports long-term relationships with construction professionals who depend on reliable material properties.